All products featured are independently chosen by us. However, SoundGuys may receive a commission on orders placed through its retail links. See our ethics statement.

What is a MEMS speaker?

January 18, 2024

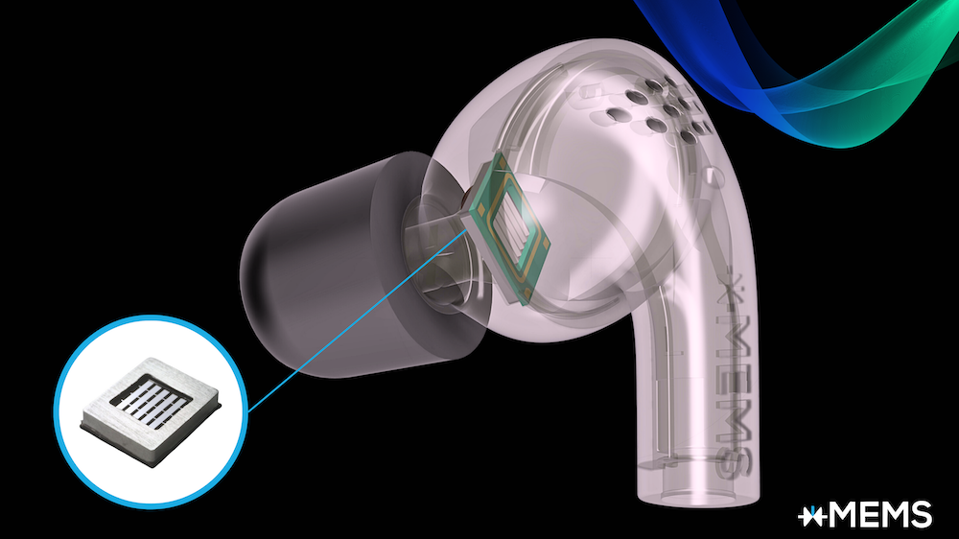

MEMS speakers are the most significant innovation in speaker technology in years. While this advance hasn’t received much attention, its importance in the headphone world should be compared to the introduction of SSD technology in computer hard drives. With full-range audio reproduction, compact size, and low power requirements, MEMS speakers will see rapid adoption in audio products like true wireless earphones (TWS), hearing aids, smart glasses, and more.

This article explains what MEMS speakers are, how they work, and why we will soon start hearing them everywhere.

How are MEMS speakers different?

The tiny speaker drivers in headphones that produce the sound you hear haven’t changed much since they were first invented. The moving coil speaker was developed over a hundred years ago and has been slowly refined. The audio industry still relies on this technology, and the most common headphone driver type still uses a coil of wire and a magnet assembly to move a diaphragm that moves air to produce sound. MEMS speakers use a different principle of operation to move air and make sound.

Microelectromechanical systems (MEMS) combine microelectronic circuitry with micrometer-sized mechanical components. MEMS technology is typically used for sensors, actuators, switches, gyroscopes, accelerometers, and microphones. Most microphones in consumer electronics products have been MEMS-based for over ten years. And now, it’s the turn of the micro speaker to make the same transition.

How do MEMS speakers work?

Most MEMS speakers, sometimes called solid-state drivers, use the piezoelectric effect for their motor actuation. This effect exploits a property of certain materials to become electrically polarized under strain and stress, a phenomenon first discovered in the mid-18th century. Piezoelectric materials are specific types of crystals that convert mechanical energy into electrical energy. The energy conversion works both ways, and the principle used for piezo speakers is sometimes called the inverse piezoelectric effect.

For a piezo MEMS speaker to create mechanical energy (motion), cantilevers are created by applying a voltage generated between electrodes to a piezoelectric crystal layer, causing it to change shape. This layer is mounted to a substrate like a silicon plate, so as the top layer contracts, both layers bend upwards. The working principle of a MEMS loudspeaker involves using a spring-like structure that incorporates multiple bending cantilevers to move a central mass called a piston, creating movement.

For a speaker to radiate sound, it has to move air. For a MEMS speaker to do this effectively, the small layer of crystalline structure experiencing the piezoelectric effect is connected to a membrane that spreads the motion over a larger surface area. This diaphragm is moved by the piezo MEMS motor, and sound is produced.

Electrically, MEMS speakers behave as a capacitive load, requiring higher voltage (up to 30 volts peak-to-peak) but with almost negligible current flow — though the total power consumption is comparable to traditional loudspeakers. It’s important to note that in this application, the piezoelectric material also requires a DC bias voltage to be applied (around 15 volts is typical). The bias voltage is needed because the piezoelectric material can only contract. Since you want to move it in either direction from stationary (necessary to reproduce an audio waveform), you first need to contract it to the halfway point using a fixed (bias) voltage. You can then move it up and down with the signal applied.

Since, to the amplifier, MEMS speakers look like capacitors, the power is primarily reactive and can be reused in the system, which can be exploited to reduce their power consumption further.

What are the benefits of MEMS speakers?

The first benefit of MEMS speakers is their size. Traditional coil and magnet-based speakers have physical limitations on their minimum dimensions that don’t apply to MEMS speakers. Rather than relying on a bulky magnet-coil actuator, MEMS speakers use integrated piezo-actuators to propel the membrane and generate sound. Since the structure — mainly comprised of the diaphragm and a thin silicon piece — is entirely made with precision MEMS processes, it can be made with a thickness of less than one millimeter. This, in turn, means the total mass of the moving elements is incredibly low. Silicon fabrication processes allow reflow soldering, streamlining production with extremely tight tolerances, resulting in much lower power-to-part variation with fewer failures.

While manufacturers benefit from easier testing, scalability, and consistency, consumers will experience improved audio quality thanks to some unique characteristics of the new technology. The faster mechanical response — 150 times faster than current technology — means a flat frequency response, better phase response, and lower distortion due to the diaphragm’s material characteristics. Because MEMS speakers are inherently more efficient at high frequencies (potentially extending up to 80kHz), they can easily meet Japan Audio Society’s high-res audio certification, for example.

Additionally, the power consumption of MEMS speakers can be further reduced by taking advantage of their electrical load characteristics (see FAQ above).

Based on these benefits, MEMS speakers are ideal for miniaturized audio devices such as earbuds, hearing aids, and wearables like smart glasses and AR/VR headsets. Acoustic measurements we’ve made on one early example of a TWS earbud using MEMS speaker technology, the Creative Aurvana Ace 2, show that the promised sonic benefits are born out, exhibited through their excellent MDAQS results shown above.

USound developed and has already shipped several hundred thousand MEMS speakers, and it says it was the first to market. USound overcame the limitation of traditional piezo transducers with an innovative MEMS concept that’s proven to generate relatively large acoustic displacement.

TDK, best known for its sensors and other electronics components, created its PiezoListen microspeakers using twelve stacked layers of piezoelectric material based on a haptic device. With a response down to 200 Hz, they are intended for consumer products such as tablet computers and TVs.

Audio Pixels is one of the pioneers in directly generating sound from a digital audio stream with MEMS devices. Its silicon chip speakers can be stand-alone or cascaded in multiples to achieve the required performance.

GraphAudio has developed an electrostatic speaker, but a pure graphene diaphragm is used instead of a metalized polymer film diaphragm. Its initial products are earphones using a graphene diaphragm sandwiched between electrodes.

Fraunhofer, the German research institute — responsible for the MP3 compression algorithm — has developed both piezo and capacitive (electrostatic) all silicon MEMS speakers and is working on increased SPL and reduced distortion through optimization.

Sonion has electrostatic MEMS tweeters (electret) designed for use as tweeters that offer superior performance to traditional balanced armatures in IEMs. It enables electrostatic performance in IEMs without the usual separate power supply for stepping up the voltage and supplying bias to the driver.

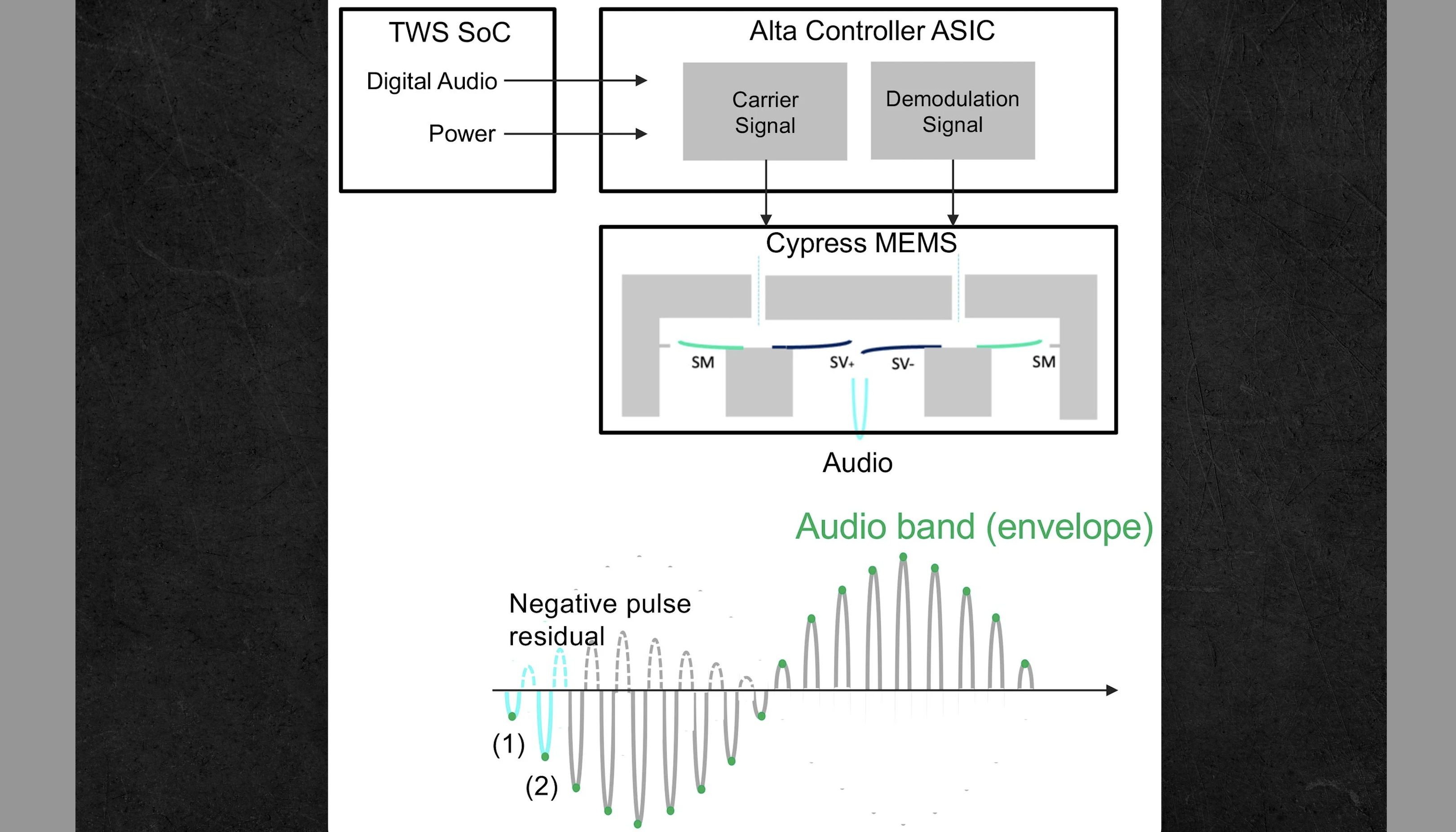

For over four years, xMEMS labs has been working on an all-silicon solid-state speaker driver with plans to roll out the tech more widely in 2024. With its latest generation prototype Cypress, xMEMS is pushing a new technology that “reinvents the transduction mechanism.” Moving beyond conventional push-pull transduction in the audible frequency band, the company has made advances in ultrasonic amplitude modulation.

What is ultrasonic amplitude modulation?

xMEMS’ ultrasonic amplitude modulation is an innovation of MEMS speaker technology that turns ultrasonic (very high-frequency sound) waves we can’t hear into full-frequency audio we can listen to — in a highly efficient way. The process is highly innovative. First, a custom integrated circuit (IC) modulates an ultrasound carrier signal with the wanted audio signal from the source device. This produces an ultrasound signal whose amplitude envelope is shaped by the incoming audio signal. This combined signal drives a pair of cantilevers in the MEMS speaker, generating acoustic ultrasonic pressure waves inside a closed chamber in the speaker housing. A second demodulator signal controls the opening and closing of tiny flaps that vent the speaker’s chamber, producing a series of pressure bursts to demodulate the ultrasonic wave synchronously. The envelope of these pressure bursts forms the acoustic signal we hear. The sound envelope of ultrasonic pulses is an exact acoustic copy of the source signal, so Cypress produces a faithful sound reproduction across all frequencies.

This technique results in a massive increase in efficiency, analogous to class D‘s improvements of traditional class AB amplifier architectures. The acoustic output is up to 40 times louder than xMEMS’ prior-generation speakers that used traditional transduction in the audible frequency band. xMEMS claims that its latest generation prototype, Cypress, shown for the first time at CES 2024, can reach more than 140 dB (SPL) even at 20 Hz, the lowest frequency we can hear. These drivers could also deliver more effective active noise cancelation (ANC) in earbuds and headphones if proven out.

Since this approach works for sound generation in free air as well as in-ear applications, it offers potential benefits in low-frequency generation for small format loudspeakers. This gives the technology a path to other consumer audio devices that require more output, such as smartphones and tablets.

What are the disadvantages of MEMS speakers?

MEMS are unsuitable for niche applications since fabrication and assembly costs are prohibitively high for small quantities. The test equipment needed to characterize the quality and performance can also be expensive. Because MEMS elements get more costly as they get larger, the MEMS speakers we have seen so far are small and do not target larger format applications.

From a practical perspective, the major downside to MEMS speakers is that they require a constant bias voltage, like electrostatic headphones. This means that MEMS drivers can’t be used with typical source equipment and need dedicated electronics to drive them. However, MEMS can be powered by integrated circuitry driven by the battery of true wireless (TWS) earbuds, making them an ideal platform to roll out the technology.

What’s next?

MEMS speaker driver technology provides distinct advantages compared to dynamic and balanced armature speakers. Manufacturers like Creative Labs, Noble Audio and Singularity Industries have already incorporated these solid-state drivers into earbud products. They promise excellent sound quality, use fewer materials, and are virtually indestructible while being more cost-effective. More examples will be released in 2024, so expect to hear more about solid-state MEMS-driven earbuds.